Smart Membrane-Based System for Cheaper and Sustainable Water Desalination

Cost saving and real-time performance monitoring for membrane-based desalination

Technology summary

Among conventional and innovative water desalination technologies, membrane distillation (MD) has great potential for providing both a sustainable and high-quality water supply.

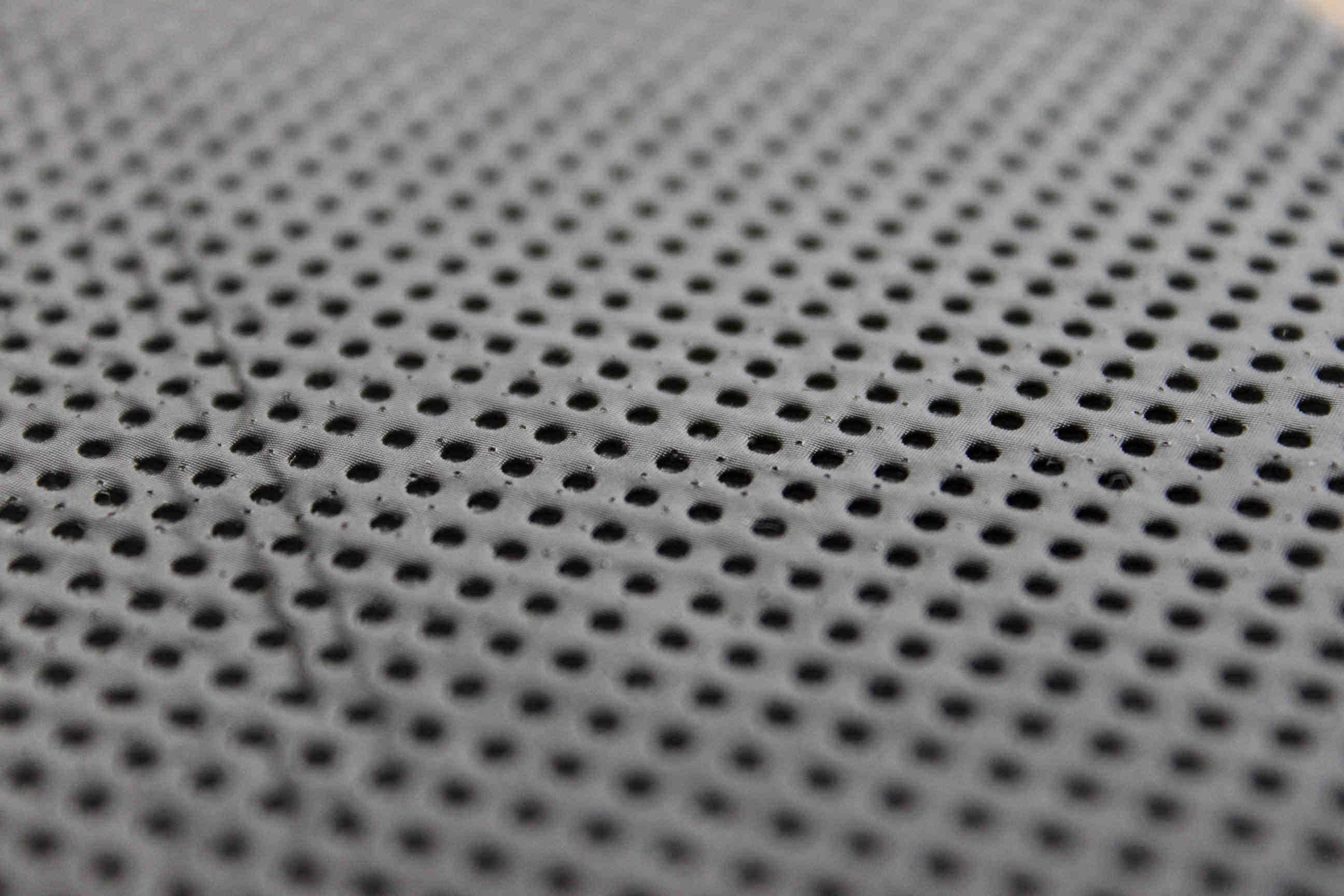

MD is a thermally-driven membrane-separation process. With this process, only water vapor passes through the microporous hydrophobic membranes. Current membrane distillation technologies are prone to membrane fouling and scaling. This can reduce production rate, cause a system shutdown for cleaning and may increase operational costs.

This new technology provides an early detection for membrane fouling and real-time characterization of the membrane’s overall condition. It supports decision making for membrane cleaning and reduces operational costs. This is achieved through advanced soft sensing algorithms, which rely on a physical model of the process and readily available outlet temperatures. The method estimates the temperature inside the module, which can be used to find optimal operating conditions.

How it works

Monitoring a process such as water desalination often requires taking physical measurements and understanding the overall state of the system. However, the main challenge for membrane-based desalination processes is the limited access to data. If additional temperature measurements from the membrane surface could be obtained, they would provide crucial information on the condition of the membrane.

This invention provides additional temperature measurements without using additional sensors. The measurements can be used to detect anomalies at an early stage.

The software combines a mathematical model with readily available real-time measurements. It analyzes outlet temperatures and production rates to estimate the membrane surface temperature and characteristics. The deviation of the estimated membrane characteristics from their nominal values and changes in the temperature values at the membrane surface are analyzed to provide a decision about the status of the membrane.

Why it is better

This technology uses soft sensing, which requires fewer sensors to estimate the condition of the membrane and the spatial temperature distribution. This, in turn, reduces the manufacturing cost. It also provides the advantage of localizing the anomaly at the membrane level. This allows for a better monitoring and cheaper cleaning process.

IP protection

Patents pending

Invention track code

2015-065 and 2016-012

Benefits

- Monitoring of the membrane distillation system performance

- Early detection of fouling and other potential anomalies

- Spatial localization of the anomalies along the membrane

- Does not require extra sensors as the estimation is done using software

- Estimation of the spatial temperature and membrane characteristics

Applications

- Membrane based water desalination systems (e.g., membrane distillation and reverse osmosis)