Highly Efficient and Effective Polymer Injection Process for Enhanced Oil Recovery

Potential process to boost oil recovery over conventional continuous polymer flooding

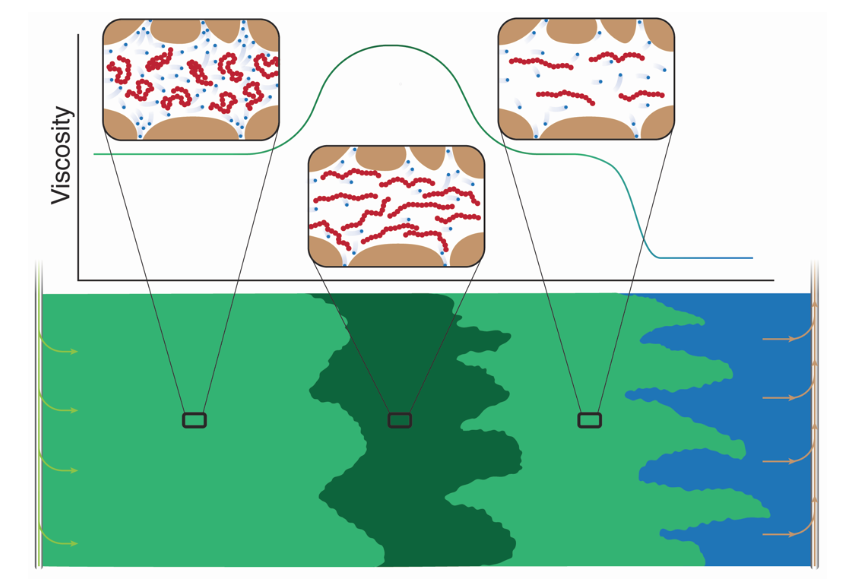

This KAUST patented pending technology demonstrates a simple, yet effective polymer injection scheme that relies on the cyclical injection of low-salinity, low-concentration of polymer slugs chased by high-salinity, high-concentration of polymer slugs. This scheme achieves two goals:

- The polymer viscosities are low in the near wellbore, which enables high injectivity.

- The in-situ mixing of the slugs produce high-viscosity polymers, which improves the sweep efficiency.

Numerical simulations are used to demonstrate the concept, which exploits known characteristics of polymers in terms of their rheology and interactions with the porous media. Various 1D, 2D and 3D simulations are considered using a research simulator, UTCHEM, to illustrate the mechanisms behind the proposed injection scheme.

Technology Summary

How It Works

The process is demonstrated through the numerical results and these results demonstrate the new process for polymer flooding using compositionally tuned slugs. First, the effect of inaccessible pore volume and adsorption in accelerating and retarding, the polymer component was shown and compared it with reference tracer, such as salt concentration. The numerical simulations were constrained to core flood data obtained from the literature in order to emphasize the consequence of both inaccessible pore volume and adsorption on the polymer transport through porous media. Once this process is carried out, one, two, and three-dimensional two-phase flow simulations are carried out to show the benefit of the new displacement process over the alternatives (e.g., continuous polymer injection and water flooding).

Why It Is Better

the reservoir pressure and to improve oil extraction. After some time of water injection, water breaks through at the production wells and the process becomes gradually less effective, and therefore reaches maturity. Most of the oilfields worldwide and in particular in the Middle East are maturing. Waterflood is therefore becoming less effective. One of the most attractive EOR techniques used to improve sweep efficiency is polymer flooding. This process has the potential to boost oil recovery over conventional continuous polymer flooding, and most importantly, to preserve polymer injectivity while achieving higher polymer solution viscosity in situ using the same chemical mass.

IP Protection

KAUST has a patent pending for this technology.

Benefits

- In terms of polymer solution rheology, this technology benefits from polymers whose viscosity can be controlled by changing salt content..

- It is has applications in polymer-rock candidates that have low adsorption, low salinity-induced adsorption changes, and high inaccessible pore volume.

- For a fixed polymer-rock system, the process can be optimized in terms of the composition of the slugs and cycle size

- Provides electronics with longer battery lives and performance as well as energy conservation and storage

Applications

- One key limitation of polymer flooding is related to the ability of polymer to be effective in low permeable reservoirs.

- KAUST technology extends the range of applicability of polymer as it allows target low permeable reservoirs that may not be economical with the existing methods.

- All oilfield in KSA, and the world could benefit from this technology.