Low Cost, High-Performance Ultra Filtration Membranes

Greatly improves particle selectivity and separation capability while reducing costs

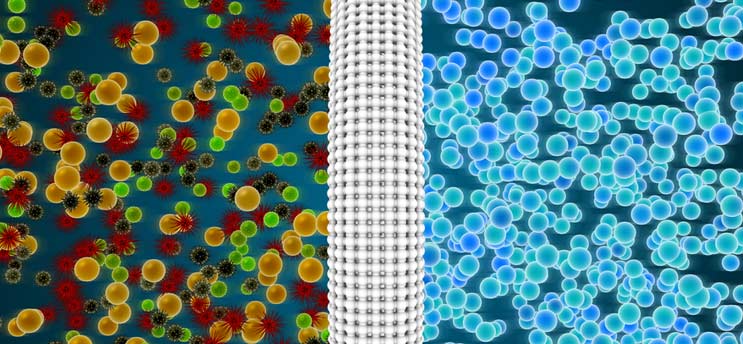

This patent-pending polymeric ultrafiltration membrane, developed through a novel manufacturing technique, offers unprecedented narrow pore size distribution at the nanoscale. Designed to meet the need for smaller and more uniform pore size, these membranes have pore diameter variations ranging from 1 to 1.2 standard diameters—a measurement never before achieved in commercial production. The simple manufacturing method significantly improves particle selectivity and separation capability by combining a standard industry process with the self-assembly ability of block polymers. The result is the fast, efficient, and low-cost production of greatly improved membranes. The membranes can be used in high-end ultrafiltration applications, including pharmaceutical manufacturing, water filtration (including the safe removal of viruses), and medical research.

Technology Summary

This membrane was developed to overcome the overly broad pore distribution properties of commercially available membranes that result in poor separation capabilities.

How It Works

KAUST’s innovative manufacturing technique combines the standard industrial process of phase inversion with the self-assembly ability of block copolymers (e.g. polyvinylpyridine or polyethylen glycol). Adding a metal salt facilitates the self-assembly of the polymers, which organize themselves into micelles that become pores. The solution is cast to a film, evaporated, and then immersed in a liquid to form the membrane. The entire process takes just 30 seconds.

KAUST’s innovative manufacturing technique combines the standard industrial process of phase inversion with the self-assembly ability of block copolymers (e.g. polyvinylpyridine or polyethylen glycol). Adding a metal salt facilitates the self-assembly of the polymers, which organize themselves into micelles that become pores. The solution is cast to a film, evaporated, and then immersed in a liquid to form the membrane. The entire process takes just 30 seconds.

Why It Is Better

There are no comparable products on the market that produce pore sizes in membranes as uniform as those produced using this new technology. Current commercially available ultrafiltration membranes typically have a 1 to 6x pore size distribution ratio, while KAUST’s membranes have well defined pores and a pore size distribution of only 1 to 1.2x. This significantly improves the membrane’s separation capabilities and enables the removal of extremely small particles such as viruses from water and proteins. Because these membranes have consistent pore sizes, this technology also greatly increases flux, allowing the fluid to flow equally through all pores. Membranes made using this process have a measured flux of 800 L/m2/hr. This results in longer lasting membranes and higher flow properties compared to currently available membranes. Additionally, this manufacturing technique results in membranes with half the production costs of current ultrafiltration membranes.

IP Protection

KAUST has several patents pending for this technology.

Invention Track Code

2010-012

Benefits

- Precise: Extremely small pore distribution of 1 to 1.2x pore size distribution as compared to currently available membranes that offer 1 to 6x.

- Reliable: Produces reliable separation of molecules with similar molecular weights.

- Robust: Increases flux to provide longer lasting and higher flow properties when compared to currently available membranes.

- Inexpensive: Costs for production are half that of comparable ultrafiltration membranes.

Applications

The membranes can be used in high-end ultrafiltration applications to separate very small items such as viruses from water or proteins.

- Water filtration

- Pharmaceutical manufacturing

- Medical research and development

- Medical instruments