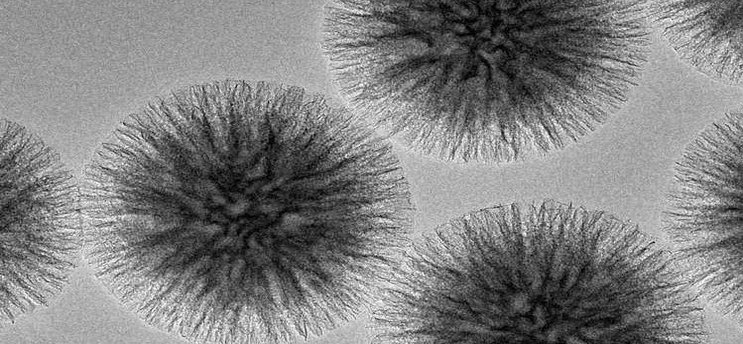

Fibrous Silica Nanospheres (KCC1)

This product is ready for material testing and industrial manufacturing

KAUST’s novel fibrous silica nanospheres technology (KCC1) offers exceptional performance in comparison to other types of silica, making it ideal for use in a wide variety of commercial catalysts and sorbent applications. These advances are expected to revolutionize the field of silicasupported catalysts, enabling neverbeforepossible applications for silica in catalysis.

KCC1 has a high surface area due to the tailormade fibrous and spherical morphology. This has resulted in advanced material properties, such as high mechanical and thermal stability, as well as excellent dispersion in aqueous and nonaqueous media, which further enhance KCC1′s stability as a catalyst support material.

These intrinsic advanced properties have resulted in performance features that have made this material commercially viable in wide range of applications, such as catalyst support and sorbent applications, coatings, petroleum/petrochemical processes, carbon dioxide (CO2)capture, hydrogen storage, cosmetics, and drug delivery.

Technology Summary

Our researchers used a hydrothermal synthesis (HTS) process to produce KCC1. The existence of uniform fibrous channels in KCC1 renders molecular accessibility to particle surface efficient in comparison to other types of silica and catalyst support materials. Furthermore, the process of making KCC1 has been successfully optimized, and a pilot scaleup production has reached 1 kg of KCC1 with 100 percent repeatability.

How It Works

An inhouse scaleup facility with a 20liter reactor has been commissioned to render the chemical process more industrially friendly, as well as test various market applications where KCC1 can be used as a novel silica material. Now KAUST has the capability of producing 1 kg samples for industry study and testing. We also succeeded in cutting down the cost of production by more than 50% by reducing chemicals and accelerating production times.

Why It Is Better

Given the growing need for silica nanospheres, much research has been done to control the shape, structure, and pore size using mesoporous silica. However, the performance, and therefore the applicability, of mesoporous silica has been hindered by the limitation in accessibility to the active sites within the porous structure for many reasons, such as clogging of the pores by the sintering of active metals.

KCC1 offers a unique alternative shape, other than porous, that has never before been seen in silica materials: a fibrous surface morphology arranged in a threedimensional structure to form spheres. Unlike traditional porebased silica, these nanospheres possess a fibrous structure that dramatically increases accessibility to most of the available surface area. This, in turn, increases catalytic activity significantly.

Tests performed on this technology so far have demonstrated that KCC1 offered better performance than other silicabased systems (e.g. commercially available SBA15, MCM41) in various applications related to catalysis and/or sorption. The KCC1 production process is under continuous development and improvement to ensure industrial compatibility and widen its commercial applications.

IP Protection

KAUST has several patents pending for this technology.

Invention Track Code

2010-013

Benefits

- High surface area: Increased surface area due to the particles’ structure and shape

- High thermal stability: Up to 800 °C

- High mechanical stability: Up to 216 MPa

- Excellent dispersion

Applications

- Catalysts supports for many industrial processes

- CO2capture

- Hydrogen storage

- Sorbent applications such as in chromatography (column packing)

- Paints

- Drug delivery