Flash μ-Fluidics: A Rapid Prototyping Method For Fabricating Microfluidic Devices

A method for in situ fabrication of microfluidic devices

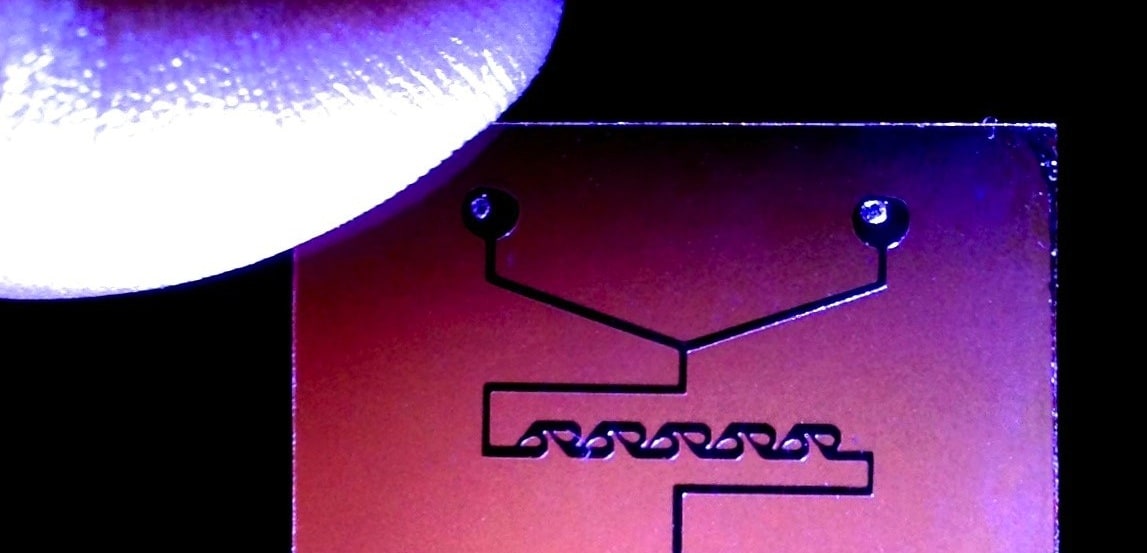

Microfluidics has advanced in terms of designs and structures, however, fabrication methods are either time consuming or expensive to produce, in terms of the facilities and equipment needed. A fast and economically viable method is provided to allow, for example, research groups to have access to microfluidic fabrication. Unlike most fabrication methods, a method is provided to fabricate a microfluidic device in one step. A resolution of 50 micrometers was achieved by using maskless highresolution digital light projection (MDLP). Bonding and channel fabrication of complex or simple structures can be rapidly incorporated to fabricate the microfluidic devices.

Technology Summary

Fabrication of a lab on a chip final product can be done in just one step. A digital light projector (DLP) can be used as a maskless lithography system. The channels can be fabricated within 2 – 20 seconds. At a specific distance the projected light from the DLP can be focused on at least one of the surfaces or substrates that is transparent to light. The light can solidify (cure) selected sections or portions of the light sensitive material between the two surfaces to form the microfluidic channels.

How It Works

A complete microfluidic device can be fabricated in 2.8 seconds. The fabricated microfluidics devices can be integrated with analytical devices that enable fluid handling and quantitative analysis. Such applications are important for potential applications in medicine, healthcare, and environmental monitoring. This method, when fabricated with biocompatible resin, can also be used to print microfluidic chips to culture cells.

Why It Is Better

The more recent 3D printing technology has the advantage of simplicity and low setup costs. Setup costs for existing technologies are substantially greater and require a clean room facility. These methods require hours of fabrication time and often need trained personnel. A further important benefit of the flash microfluidics method is that electrodes or sensors are easily integrated while introducing various surface combinations yet without introducing leakages to the lab on chip device.

IP Protection

KAUST has several patents pending for this technology.

Invention Track Code

2015-110

Benefits

- Fast setup and fabrication time

- Easy to change designs thus good for prototyping

- Low initial setup costs. ($3000 or less)

- $0.5 or less material costs for the total chip fabrication

- Easy probed with custom made electrical and fluidic connections

- Efficient in fabricating various devices

- Integrating electrodes or sensors and channels without any leakages

Applications

- Medical Diagnostics

- Droplet Generators

- Microfluidics mixing and gradients

- Rapid prototyping for Researchers