Early in 2011, KAUST’s Catalysis Center discovered a new fibrous silica nanospheres material called KCC-1. As part of our commercialization efforts, we’ve since established a scale-up facility in KAUST’s Innovation Cluster using a 20-liter reactor for production of KCC-1. Now, we are making KCC-1 at a pilot scale, producing a kilogram per batch of the material and sharing samples with interested companies.

Ongoing Discovery and Improvement

The KCC-1 production process is under continued development and improvement to ensure industrial compatibility and broaden its commercial applications. Researchers are improving the material in two ways: 1) increasing the compound’s production volume, and 2) reducing or eliminating certain chemicals used in production. So far, we have cut production cost by more than 50% by reducing chemicals and accelerating production time.

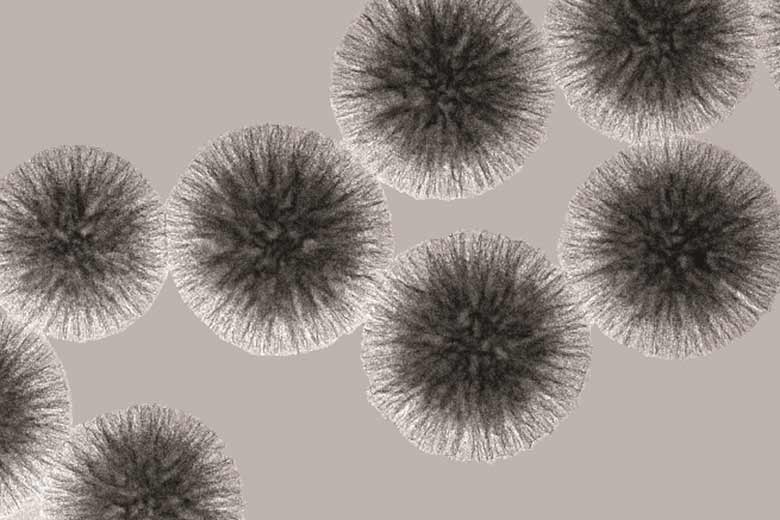

Like many great innovations, KCC-1 was discovered by accident. (This makes it a great example of blue-skies research.) KCC-1’s primary researcher was testing variations of templating media in aqueous and nonaqueous solutions. While performing experimental trials, a never-before-seen compound emerged: spherical silica particles with short, bristly fibers. The material is revolutionary in conventional and niche silica applications; from cosmetics and catalyst supports to pharmaceuticals.

A Fibrous Morphology for Better Application and Performance

KCC-1 spheres are 100-250 nm across, and the spheres’ fibers can be 10 nm long or more. Why does this matter? The particles’ fibers create a significantly higher surface area than conventional silica particles with no fibers. High surface area is an important variable in conducting catalytic reactions efficiently.

In fact, with an average surface area between 500 and 650 m2/g, KCC-1 has the highest surface area among other silica products which makes for extremely efficient industrial applications.

Creating a Technology Springboard

We think of KCC-1 as a “technology platform.” This means that it has more than a single, distinct purpose: rather, we hope it serves as a springboard for other new, as-yet-unimagined applications. After carbon, silica (or silicon dioxide) is the most common ingredient in most commercial and industrial products, from paint and coatings fillers, to sunscreen, cosmetics, drug delivery, and catalyst supports.

KCC-1’s unique properties, including high thermal and mechanical stability, low density, and excellent dispersion in aqueous and nonaqueous media, open the door for even more product applications. At KAUST, we look forward to seeing KCC-1 put to work.

If you are interested in learning more or obtaining a sample of KCC-1, feel free to contact me. Our flexible business practices make joint product development, patent licensing, and other collaborative relationships easy for partners.

Fibrous Silica Nanospheres (KCC-1)

This post is archived and may contain outdated information.