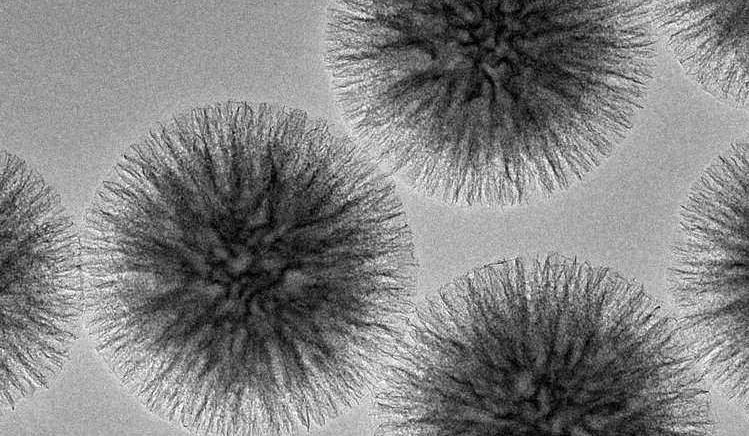

It is important to properly develop a product from the laboratory to the manufacturing floor. To encourage this step, KAUST has invested in a number of scale-up labs. One the most commercially promising projects to come out of these ‘innovation garages’ has been the development of an industrial viable process (patented by KAUST) to produce a fibrous silica nanospheres material called KCC-1.

KCC-1 has the potential to revolutionize the field of silica applications, especially in the petrochemicals, cosmetics and clean-tech sectors.

Silica is often used as a thickener/additive in a number of industrial products. However, currently available silica products have a number of limitations. For example, many niche silica products are very expensive—as high as US$2000 to $10,000 per kilogram. Additionally, and from a supply chain perspective, the precursors needed to make specialty silicas may be difficult to obtain and often require burdensome paperwork. In addition, silica products are often aggregates forming a lumpy texture in coatings or emulsions and do not disperse as required. To deal with this problem often requires energy intensive machinery and equipment such as vortex machines to ensure smooth dispersion.

KCC-1 addresses these existing problems and represents a significant achievement by KAUST’s technology transfer team in narrowing the gap between technology concepts in the lab and their manufacturing and practical adoption by a variety of industries. In addition, it is cheap to produce (US$15 to US$20 per kilogram) and uses commercially available chemicals instead of research laboratory grades. Hence, in comparison to its commercially available counterparts in catalysis, cosmetics or fillers, KCC-1 can be seen as a game changer due to its low price.

KCC-1 could also be extremely useful to the clean tech sector, especially for CO2 capture. In an era when many governments and companies around the world have to meet ambitious reduction targets, functionalization of KCC-1 would help these entities achieve their goals. Existing methods to deal with CO2 are cumbersome and usually involve trapping CO2 in ammonium based solutions, which can have negative environmental impacts. However, KCC-1 provides a more efficient and useful CO2 capture process allowing absorption and desorption of the CO2 and hence can be used in manufacturing of value-added products.

Kilo lab

The Kilo Lab has been commissioned recently to assist with the scaling up of fine chemicals, including pharmaceutical active ingredients and organic based products. Being the first of its kind in the region, it is anticipated this facility will be utilized by local and regional industries for product development, training and other technical work. The Kilo Lab will have a positive economic impact in enhancing advanced industries and will be pivotal in attracting pharmaceutical companies to test their innovations at KAUST.